Vertical qhuav mortar ntau lawm kab CRL-2

Product Detail

Taw qhia

Vertical qhuav mortar ntau lawm kab

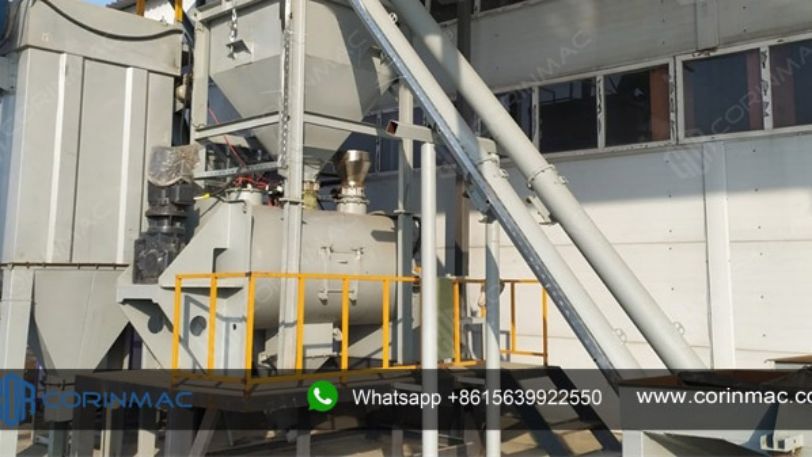

Vertical mortar ntau lawm kab CRL series, tseem hu ua tus txheej txheem mortar ntau lawm kab, yog ib tug ua tiav cov cuab yeej rau batching tiav cov xuab zeb, cementitious cov ntaub ntawv (cement, gypsum, thiab lwm yam), ntau yam additives thiab lwm yam raw khoom raws li ib tug tshwj xeeb daim ntawv qhia, mix. nrog ib tug tov khoom, thiab mechanically packing tau qhuav hmoov mortar, nrog rau raw khoom cia silo, ntsia hlau conveyor, hnyav hopper, additive batching system, thoob of elevator, pre-mixed hopper, tov khoom, ntim tshuab, plua plav collectors thiab tswj system.

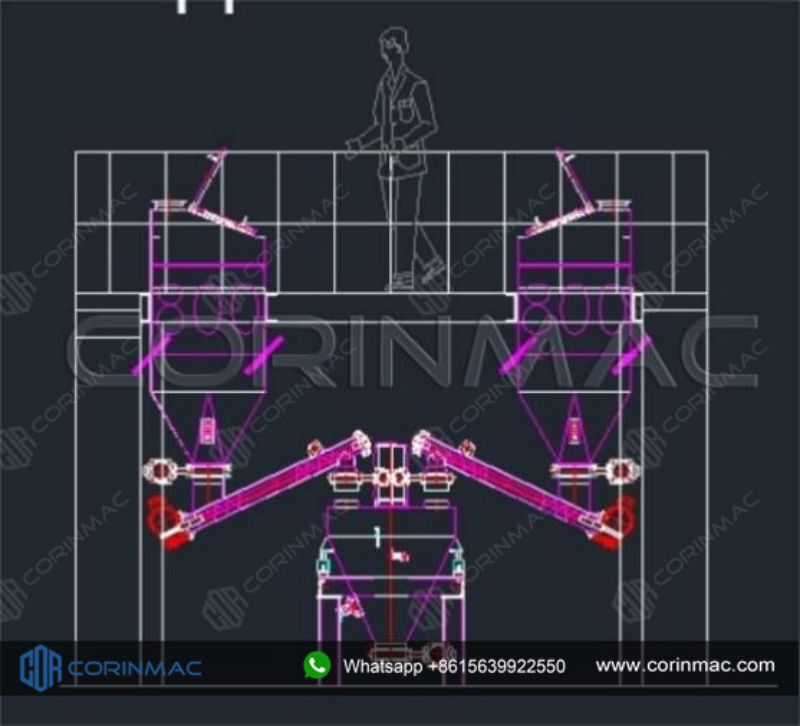

Lub npe ntawm ntsug mortar ntau lawm kab los ntawm nws cov qauv ntsug.Pre-mixed hopper, additive batching system, tov khoom thiab ntim tshuab yog teem rau ntawm steel qauv platform los ntawm sab saum toj mus rau hauv qab, uas yuav muab faib ua ib-pem teb los yog ntau-pem teb qauv.

Cov kab ntau lawm yuav txawv heev vim qhov sib txawv ntawm qhov yuav tsum tau muaj peev xwm, kev ua tau zoo, cov khoom siv muaj pes tsawg leeg thiab qib ntawm automation.Tag nrho cov kab ntau lawm tuaj yeem kho raws li tus neeg siv khoom qhov chaw thiab pob nyiaj siv.

CRL-2 series ntau lawm kab suav nrog

• Raw khoom nqa thiab conveying khoom;

• Cov khoom siv raw khoom cia

• Vibrating npo

• Batching thiab Weighing system

• Tov khoom thiab ntim tshuab

• Tswj System

• Cov cuab yeej pabcuam

Raw khoom lifting thiab conveying khoom

Lub thoob of elevator

Lub thoob of elevator yog tsim los rau kev thauj mus los txuas ntxiv ntawm cov khoom siv xws li xuab zeb, gravel, crushed pob zeb, peat, slag, thee, thiab lwm yam hauv kev tsim cov khoom siv hauv tsev, tshuaj, metallurgical thiab lwm yam lag luam.

Ntsia hlau conveyor

Screw conveyor yog tsim rau kev xa cov khoom tsis muaj kuab xws li hmoov qhuav, cement, thiab lwm yam. Nws yog siv los thauj cov hmoov qhuav, cement, gypsum hmoov thiab lwm yam khoom siv raw rau cov khoom sib tov ntawm cov kab ntau lawm, thiab thauj cov khoom sib xyaw rau cov khoom tiav hopper.Qhov qis kawg ntawm cov ntsia hlau conveyor muab los ntawm peb lub tuam txhab yog nruab nrog lub hopper pub, thiab cov neeg ua haujlwm muab cov ntaub ntawv raw rau hauv lub hopper.Cov ntsia hlau yog ua los ntawm alloy steel phaj, thiab lub thickness yog sib haum mus rau txawv cov ntaub ntawv yuav tsum tau conveyed.Ob qhov kawg ntawm lub conveyor ncej txais yuav ib tug tshwj xeeb sealing qauv los txo cov kev cuam tshuam ntawm plua plav ntawm cov kabmob.

Cov khoom siv raw khoom cia

Xuab zeb hopper

Cov xuab zeb hopper feem ntau yog tsim los ntawm lub cev hopper (qhov ntim thiab ntau ntawm lub hopper lub cev yog kho raws li qhov xav tau tiag tiag), kev txhawb nqa steel qauv, vibrator, thiab qib ntsuas, thiab lwm yam. Yuav kom txuag tau tus nqi thauj mus los, tus neeg siv khoom. tuaj yeem ua rau hauv zos, thiab peb yuav muab cov qauv tsim thiab tsim cov duab kos.

Vibrating npo

Lub vibrating npo yog siv los sieve cov xuab zeb rau hauv qhov xav tau qhov loj me.Lub vijtsam lub cev tau txais cov qauv kaw tag nrho, uas tuaj yeem txo cov plua plav tawm thaum lub sijhawm ua haujlwm.Screen lub cev sab phaj, fais fab kis daim hlau thiab lwm yam khoom yog ua los ntawm high-zoo alloy steel daim hlau, nrog siab yield zog thiab ntev kev pab cuam lub neej.

Batching thiab hnyav system (cov ntaub ntawv tseem ceeb thiab cov khoom ntxiv)

Cov khoom tseem ceeb uas hnyav hopper

Qhov hnyav hopper muaj hopper, steel ncej, thiab load cell (qhov qis ntawm qhov hnyav hopper yog nruab nrog lub hau ntsaws).Qhov hnyav hopper yog dav siv nyob rau hauv ntau yam mortar kab los luj cov khoom xyaw xws li cement, xuab zeb, ya tshauv, lub teeb calcium, thiab hnyav calcium.Nws muaj qhov zoo ntawm kev ceev batching ceev, siab ntsuas qhov tseeb, muaj zog versatility, thiab muaj peev xwm lis ntau yam ntaub ntawv.

Additives batching system

Tov khoom thiab ntim tshuab

Qhuav mortar mixer

Lub tshuab ziab khaub ncaws qhuav yog cov khoom siv tseem ceeb ntawm cov khoom siv khib nyiab qhuav, uas txiav txim siab qhov zoo ntawm cov mortars.Cov mortar sib txawv tuaj yeem siv tau raws li ntau hom mortar.

Ib tug ncej plough share mixer

Cov cuab yeej siv tshuab plough share mixer feem ntau yog los ntawm lub teb chaws Yelemees, thiab nws yog ib qho khoom siv feem ntau siv nyob rau hauv loj-scale qhuav hmoov mortar ntau lawm kab.Lub plough share mixer yog tsim los ntawm lub tog raj kheej sab nraud, lub ntsiab ncej, plough shares, thiab plough share handles.Kev sib hloov ntawm lub ntsiab ncej tsav lub ploughshare-zoo li cov hniav kom tig ntawm lub siab ceev kom tsav cov khoom txav ceev ceev hauv ob qho tib si, thiaj li ua tiav lub hom phiaj ntawm kev sib tov.Lub nplawm nrawm nrawm nrawm, thiab rab riam ya tau nruab rau ntawm phab ntsa ntawm lub tog raj kheej, uas tuaj yeem cuam tshuam cov khoom sai sai, kom cov khoom sib xyaw ntau dua thiab nrawm, thiab qhov sib tov zoo yog siab.

Ib tug ncej plough qhia mixer (me me tso qhov rooj)

Ib tug ncej plough qhia mixer (loj paug qhov rooj)

Ib tug ncej plough qhia mixer (Sab hmo kev kub ceev)

Khoom hopper

Cov khoom tiav lawm hopper yog kaw silo ua los ntawm alloy steel daim hlau rau khaws cov khoom sib xyaw.Sab saum toj ntawm lub silo yog nruab nrog qhov chaw noj mov, lub tshuab ua pa thiab lub tshuab nqus plua plav.Lub khob hliav qab ntawm lub silo yog nruab nrog lub tshuab pneumatic vibrator thiab lub koov tawg los tiv thaiv cov khoom los ntawm kev thaiv hauv lub hopper.

Valve hnab packing tshuab

Raws li cov kev xav tau ntawm cov neeg siv khoom sib txawv, peb tuaj yeem muab peb hom kev ntim khoom sib txawv, hom impeller, hom cua tshuab thiab cua ntab hom rau koj xaiv.Qhov ntsuas qhov ntsuas yog qhov tseem ceeb ntawm lub hnab ntim lub hnab ntim tshuab.Lub ntsuas ntsuas, ntsuas qhov hnyav thiab cov khoom siv hluav taws xob siv hauv peb lub tshuab ntim khoom yog tag nrho cov hom thawj, nrog rau kev ntsuas ntau, siab precision, rhiab tawm tswv yim, thiab qhov hnyav yuam kev yuav yog ± 0.2%, tuaj yeem ua tau raws li koj xav tau.

Tswj txee

Cov khoom siv uas tau teev tseg saum toj no yog hom pib ntawm hom kab ntau lawm.

Yog tias tsim nyog los txo cov plua plav hauv qhov chaw ua haujlwm thiab txhim kho qhov chaw ua haujlwm ntawm cov neeg ua haujlwm, lub tshuab nqus plua plav me me tuaj yeem ntsia tau.

Hauv luv luv, peb tuaj yeem ua cov qauv tsim thiab teeb tsa sib txawv raws li koj xav tau.

Installation thiab commissioning

CORINMAC muab kev pabcuam rau ntawm qhov chaw thiab commissioning.Peb tuaj yeem xa cov kws tshaj lij engineers rau koj qhov chaw raws li koj qhov yuav tsum tau ua thiab cob qhia cov neeg ua haujlwm hauv tsev los ua haujlwm cov khoom siv.Peb kuj tuaj yeem muab cov kev pab cuam qhia kev teeb tsa video.

Installation cov kauj ruam qhia

Kev kos duab

Peb cov khoom

Cov khoom pom zoo

Rotary tshuab ziab khaub ncaws nrog tsawg zog noj thiab hi ...

Nta thiab qhov zoo:

1. Raws li cov ntaub ntawv sib txawv kom qhuav, qhov tsim nyog tig lub tog raj kheej tuaj yeem xaiv tau.

2. Kev ua haujlwm du thiab txhim khu kev qha.

3. Cov khoom siv hluav taws xob sib txawv muaj xws li: roj av, diesel, thee, biomass hais, thiab lwm yam.

4. ntse tswj qhov kub thiab txias.

Kev ua haujlwm ruaj khov thiab loj conveying muaj peev xwm b ...

Lub thoob of elevator yog cov khoom siv dav siv ntsug conveying.Nws yog siv rau ntsug conveying ntawm hmoov, granular thiab bulk cov ntaub ntawv, raws li zoo raws li cov ntaub ntawv abrasive heev, xws li cement, xuab zeb, av coal, xuab zeb, thiab lwm yam. Cov khoom kub yog feem ntau qis dua 250 ° C, thiab lub lifting qhov siab tuaj yeem ncav cuag. 50 meters.

Conveying muaj peev xwm: 10-450m³ / h

Scope ntawm daim ntawv thov: thiab dav siv nyob rau hauv tsev cov ntaub ntawv, hluav taws xob fais fab, metallurgy, machinery, tshuaj lom neeg kev lag luam, mining thiab lwm yam lag luam.

saib ntxiv

Cov khoom tseem ceeb ntawm cov khoom hnyav

Nta:

- 1. Cov duab ntawm qhov hnyav hopper tuaj yeem xaiv raws li cov khoom hnyav.

- 2. Siv high-precision sensors, qhov hnyav yog qhov tseeb.

- 3. Tsis siv neeg qhov hnyav tag nrho, uas tuaj yeem tswj tau los ntawm kev ntsuas qhov hnyav lossis PLC lub computer

Durable thiab du-khiav siv conveyor

Nta:

Txoj siv sia feeder yog nruab nrog qhov sib txawv zaus ceev tswj lub cev muaj zog, thiab kev pub noj ceev tuaj yeem hloov kho arbitrarily kom ua tiav qhov zoo tshaj plaws ziab cov nyhuv ore lwm yam yuav tsum tau ua.

Nws siv daim tiab conveyor siv los tiv thaiv cov khoom to.

saib ntxiv

Vertical qhuav mortar ntau lawm kab CRL-3

Muaj peev xwm:5-10 TPH;10-15 TPH;15-20 TSI

saib ntxiv

Peb lub tog raj kheej teb tshuab ziab khaub ncaws nrog kub kub eff...

Nta:

1. Tag nrho qhov loj ntawm lub tshuab ziab khaub ncaws yog txo los ntawm ntau tshaj 30% piv rau tib lub tog raj kheej rotary tshuab ziab khaub ncaws, yog li txo cov cua sov sab nraud.

2. Lub thermal efficiency ntawm tus kheej-insulating tshuab ziab khaub ncaws yog siab li 80% (piv rau 35% nkaus xwb rau lub tshuab ziab khaub ncaws), thiab thermal efficiency yog 45% siab dua.

3. Vim lub compact installation, pem teb qhov chaw yog txo los ntawm 50%, thiab tus nqi infrastructure yog txo los ntawm 60%.

4. Qhov kub ntawm cov khoom tiav tom qab ziab yog li 60-70 degrees, yog li ntawd nws tsis xav tau lub tshuab txias ntxiv kom txias.