Vibrating npo nrog kev tshuaj ntsuam xyuas kev ua haujlwm siab thiab ua haujlwm ruaj khov

Product Detail

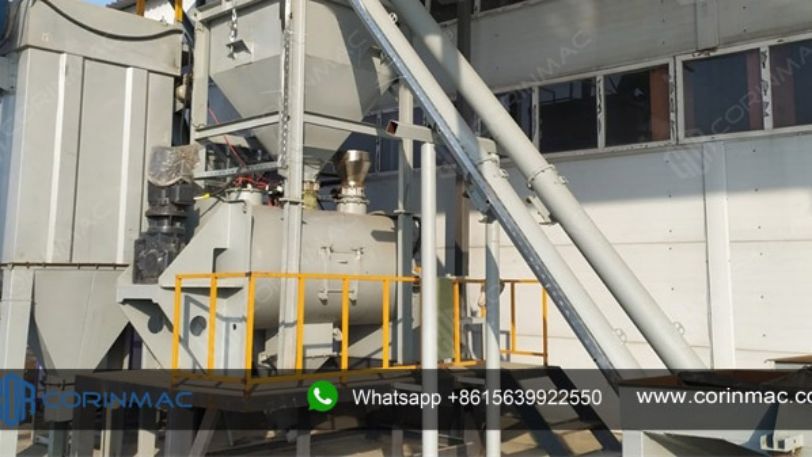

Vibrating screen qhia

Lub tshuab kuaj xuab zeb qhuav tuaj yeem muab faib ua peb hom: linear vibration type, cylindrical type thiab viav vias hom.Tsis muaj qhov tshwj xeeb yuav tsum tau, peb tau nruab nrog ib qho kev vibration hom tshuaj ntsuam tshuab hauv cov kab ntau lawm.Lub npov npo ntawm lub tshuab tshuaj ntsuam xyuas muaj cov qauv kaw tag nrho, uas txo cov plua plav tawm thaum lub sijhawm ua haujlwm.Sieve lub thawv sab phaj, lub zog xa hluav taws xob daim hlau thiab lwm yam khoom siv yog cov hlau zoo hlau hlau, nrog cov khoom muaj zog thiab kev ua haujlwm ntev.Lub zog zoo siab ntawm lub tshuab no yog muab los ntawm hom tshiab tshwj xeeb kev co lub cev muaj zog.Lub zog txaus siab tuaj yeem hloov kho los ntawm kev kho cov eccentric thaiv.Tus naj npawb ntawm cov khaubncaws sab nraud povtseg ntawm lub vijtsam tuaj yeem teem rau 1-3, thiab lub pob ncab yog nruab nrab ntawm cov ntxaij vab tshaus ntawm txhua txheej los tiv thaiv lub vijtsam los ntawm clogging thiab txhim kho kev tshuaj ntsuam xyuas.Lub linear vibratory screening tshuab muaj qhov zoo ntawm cov qauv yooj yim, txuag hluav taws xob thiab kev ua haujlwm siab, npog thaj tsam me me thiab tsis tshua muaj nqi txij nkawm.Nws yog ib qho khoom siv zoo tshaj plaws rau kev soj ntsuam cov xuab zeb qhuav.

Txoj cai ua haujlwm

Cov khoom nkag mus rau hauv lub sieve lub thawv los ntawm qhov chaw nres nkoj pub, thiab yog tsav los ntawm ob lub vibrating motors los ua kom muaj zog txaus los pov cov khoom nce.Nyob rau tib lub sijhawm, nws txav mus rau hauv txoj kab ncaj nraim, thiab tshuaj xyuas ntau yam khoom siv nrog qhov sib txawv ntawm qhov sib txawv los ntawm ntau qhov screen, thiab tawm ntawm qhov hluav taws xob sib txawv.Lub tshuab muaj cov yam ntxwv ntawm cov qauv yooj yim, kev txuag hluav taws xob thiab kev ua haujlwm siab, thiab cov qauv kaw tag nrho tsis muaj plua plav dhau.

Tom qab ziab, cov xuab zeb tiav lawm (dej cov ntsiab lus feem ntau qis dua 0.5%) nkag mus rau hauv lub vibrating npo, uas tuaj yeem ua sieved rau hauv qhov sib txawv me me thiab tso tawm los ntawm cov chaw nres nkoj raws li qhov xav tau.Feem ntau, qhov loj ntawm qhov screen mesh yog 0.63mm, 1.2mm thiab 2.0mm, qhov tshwj xeeb mesh loj yog xaiv thiab txiav txim siab raws li qhov xav tau tiag tiag.

Tag nrho-steel screen thav duab, tshwj xeeb npo qhov cuab yeej cuab tam, yooj yim los hloov lub vijtsam.

Muaj cov khoom siv roj hmab elastic, uas tuaj yeem tshem tawm qhov thaiv qhov screen.

Installation thiab commissioning

CORINMAC muab kev pabcuam rau ntawm qhov chaw thiab commissioning.Peb tuaj yeem xa cov kws tshaj lij engineers rau koj qhov chaw raws li koj qhov yuav tsum tau ua thiab cob qhia cov neeg ua haujlwm hauv tsev los ua haujlwm cov khoom siv.Peb kuj tuaj yeem muab cov kev pab cuam qhia kev teeb tsa video.

Installation cov kauj ruam qhia

Kev kos duab

Peb cov khoom

Cov khoom pom zoo

Ib tug ncej plough share mixer

Nta:

1. Lub plough sib koom lub taub hau muaj txheej hnav-tiv taus, uas muaj cov yam ntxwv ntawm kev hnav tsis kam thiab ua haujlwm ntev.

2. Fly cutters raug ntsia rau ntawm phab ntsa ntawm lub tank tov khoom, uas tuaj yeem cuam tshuam cov khoom sai sai thiab ua rau cov khoom sib tov sib xyaw thiab nrawm.

3. Raws li cov khoom sib txawv s thiab cov kev sib xyaw sib txawv, kev sib xyaw ua ke ntawm cov plough share mixer tuaj yeem tswj tau, xws li kev sib xyaw lub sijhawm, lub zog, ceev, thiab lwm yam, kom ntseeg tau tias cov khoom sib xyaw.

4. High efficiency efficiency thiab high mixing precision.

Kev ua haujlwm ruaj khov thiab loj conveying muaj peev xwm b ...

Lub thoob of elevator yog cov khoom siv dav siv ntsug conveying.Nws yog siv rau ntsug conveying ntawm hmoov, granular thiab bulk cov ntaub ntawv, raws li zoo raws li cov ntaub ntawv abrasive heev, xws li cement, xuab zeb, av coal, xuab zeb, thiab lwm yam. Cov khoom kub yog feem ntau qis dua 250 ° C, thiab lub lifting qhov siab tuaj yeem ncav cuag. 50 meters.

Conveying muaj peev xwm: 10-450m³ / h

Scope ntawm daim ntawv thov: thiab dav siv nyob rau hauv tsev cov ntaub ntawv, hluav taws xob fais fab, metallurgy, machinery, tshuaj lom neeg kev lag luam, mining thiab lwm yam lag luam.

saib ntxiv

Yooj yim qhuav mortar ntau lawm kab CRM3

Muaj peev xwm:1-3 TPH;3-5 TPH;5-10 TSI

Nta thiab qhov zoo:

1. Ob chav mixers khiav tib lub sij hawm, muab ob npaug rau cov zis.

2. Ntau yam khoom siv raw khoom yog xaiv tau, xws li lub hnab ntim khoom ntim, xuab zeb hopper, thiab lwm yam, uas yooj yim thiab hloov tau rau kev teeb tsa.

3. Tsis siv neeg qhov hnyav thiab batching ntawm cov khoom xyaw.

4. Tag nrho cov kab tuaj yeem paub txog kev tswj tsis siv neeg thiab txo tus nqi zog.

Vertical qhuav mortar ntau lawm kab CRL-1

Muaj peev xwm:5-10 TPH;10-15 TPH;15-20 TSI

saib ntxiv

Splicable thiab ruaj khov daim ntawv silo

Nta:

1. Txoj kab uas hla ntawm lub cev silo tuaj yeem tsim arbitrarily raws li qhov xav tau.

2. Loj cia muaj peev xwm, feem ntau 100-500 tons.

3. Lub cev silo tuaj yeem disassembled rau kev thauj mus los thiab sib dhos ntawm qhov chaw.Cov nqi thauj khoom raug txo qis heev, thiab ib lub thawv tuaj yeem tuav ntau lub silos.

saib ntxiv

High precision additives hnyav system

Nta:

1. Kev hnyav hnyav: siv cov khoom siv siab ua haujlwm siab load cell,

2. Kev ua haujlwm yooj yim: Kev ua haujlwm tsis siv neeg puv, pub mis, hnyav thiab thauj khoom tiav nrog ib tus yuam sij.Tom qab tau txuas nrog cov kab ntau lawm tswj qhov system, nws yog synchronized nrog cov khoom lag luam yam tsis muaj kev cuam tshuam los ntawm phau ntawv.

saib ntxiv