Qhuav ntau lawm kab nrog tsawg zog noj thiab siab tso zis ntau lawm

Product Detail

Qhuav kab ntau lawm

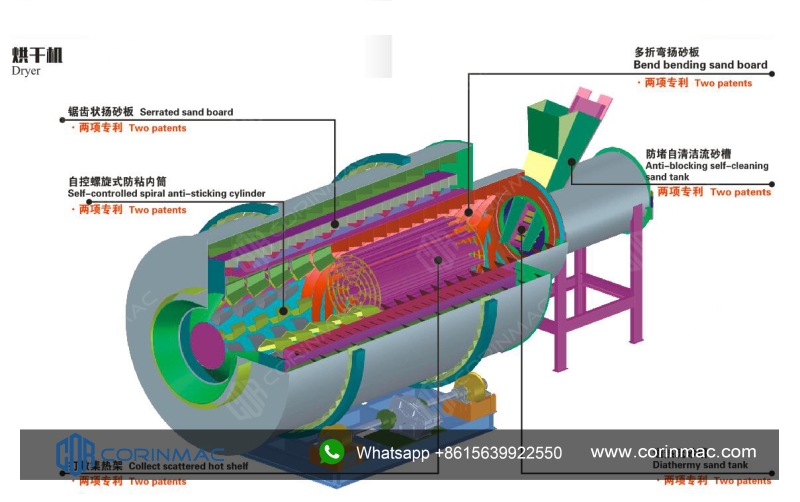

Lub tshuab ziab khaub ncaws qhuav yog ib qho ua tiav cov khoom siv rau kev ziab kom sov thiab tshuaj xyuas cov xuab zeb lossis lwm yam khoom siv ntau.Nws muaj cov nram qab no: ntub xuab zeb hopper, siv feeder, siv conveyor, burning chamber, teb tshuab ziab khaub ncaws (peb lub tog raj kheej tshuab ziab khaub ncaws, ib lub tog raj kheej tshuab ziab khaub ncaws), cyclone, pulse plua plav collector, cua ntsawj ntshab kiv cua, vibrating screen, thiab hluav taws xob tswj system .

Cov xuab zeb yog pub rau hauv cov xuab zeb ntub dej los ntawm lub loader, thiab raug xa mus rau lub inlet ntawm lub tshuab ziab khaub ncaws los ntawm txoj siv feeder thiab conveyor, thiab ces nkag mus rau lub tshuab ziab khaub ncaws.Lub tshuab hluav taws xob muab cov cua sov kom qhuav, thiab cov xuab zeb qhuav raug xa mus rau lub vibrating npo los ntawm txoj siv conveyor rau kev tshuaj ntsuam (feem ntau lub mesh loj yog 0.63, 1.2 thiab 2.0mm, qhov tshwj xeeb mesh loj yog xaiv thiab txiav txim siab raws li qhov xav tau tiag tiag) .Thaum lub sij hawm ziab, cov cua ntsawj ntshab, cua daj cua dub, pulse plua plav collector thiab cov kav dej ua rau cov plua plav tshem tawm ntawm cov kab ntau lawm, thiab tag nrho cov kab yog huv si thiab huv si!

Vim tias cov xuab zeb yog cov khoom siv feem ntau siv rau cov mortars qhuav, cov kab ziab qhuav yog feem ntau siv nrog rau cov kab qhuav mortar ntau lawm.

Cov kab ntau lawm muaj pes tsawg leeg

Wet sand hopper

Cov xuab zeb ntub dej yog siv los txais thiab khaws cov xuab zeb ntub kom qhuav.Lub ntim (tus qauv muaj peev xwm yog 5T) tuaj yeem kho raws li tus neeg siv xav tau.Lub qhov hluav taws xob nyob rau hauv qab ntawm cov xuab zeb hopper yog txuas nrog ib txoj hlua feeder.Cov qauv yog compact thiab tsim nyog, muaj zog thiab ruaj khov.

Belt feeder

Txoj siv txoj siv sia yog cov cuab yeej tseem ceeb rau kev sib npaug ntawm cov xuab zeb ntub dej rau hauv lub tshuab ziab khaub ncaws, thiab cov nyhuv ziab tuaj yeem lav tau los ntawm kev pub cov khoom sib npaug.Lub feeder yog nruab nrog qhov sib txawv zaus ceev tswj lub cev muaj zog, thiab kev pub noj ceev tuaj yeem hloov kho arbitrarily kom ua tiav cov nyhuv ziab kom zoo tshaj plaws.Nws siv daim tiab conveyor siv los tiv thaiv cov khoom to.

Hlawv chamber

Muab qhov chaw rau roj combustion, qhov kawg ntawm lub chamber yog muab nrog ib tug cua inlet thiab ib tug huab cua regulating valve, thiab sab hauv yog tsim nrog refractory cement thiab cib, thiab qhov kub nyob rau hauv lub burning chamber yuav ncav cuag 1200 ℃.Nws cov qauv yog qhov zoo thiab tsim nyog, thiab nws tau sib txuas nrog lub tshuab ziab khaub ncaws kom muab cov cua sov txaus rau lub tshuab ziab khaub ncaws.

Peb lub tog raj kheej teb tshuab ziab khaub ncaws

Peb lub tog raj kheej tig tshuab ziab khaub ncaws yog ib qho khoom siv tau zoo thiab txuag hluav taws xob txhim kho raws li lub hauv paus ntawm ib lub tog raj kheej teb tshuab.

Nws muaj peb txheej txheej nruas hauv lub tog raj kheej, uas tuaj yeem ua rau cov khoom siv rov ua dua peb zaug hauv lub tog raj kheej, kom nws tuaj yeem tau txais cov cua sov txaus txaus, txhim kho qhov kev siv hluav taws xob zoo heev thiab txo qis kev siv hluav taws xob.

Txoj cai ua haujlwm

Cov khoom nkag mus rau hauv lub tshuab ziab khaub ncaws sab hauv ntawm lub tshuab ziab khaub ncaws los ntawm cov khoom noj kom paub txog kev ziab hauv qab.Cov khoom siv tsis tu ncua lifting thiab tawg los ntawm lub puab tsaig phaj thiab mus rau hauv ib tug kauv cov duab kom paub txog thaum tshav kub kub exchanger, thaum cov khoom txav mus rau lwm qhov kawg ntawm lub puab nruas ces nkag mus rau hauv nruab nrab nruas, thiab cov khoom yog tujtaws thiab pheej pheej tsa. nyob rau hauv nruab nrab nruas, nyob rau hauv txoj kev ntawm ob kauj ruam rau pem hauv ntej thiab ib kauj ruam rov qab, cov khoom nyob rau hauv nruab nrab nruas siab absorbs lub tshav kub tawm los ntawm lub puab nruas thiab absorbs tshav kub ntawm nruab nrab nruas nyob rau tib lub sij hawm, lub ziab lub sij hawm ntev. , thiab cov khoom mus txog qhov zoo tshaj plaws ziab lub xeev nyob rau lub sij hawm no.Cov khoom siv mus rau lwm qhov kawg ntawm lub nruas nruab nrab thiab tom qab ntawd poob rau hauv lub nruas sab nraud.Cov khoom siv mus rau hauv ib lub voj voog ntau txoj hauv kev hauv lub nruas sab nraud.Cov khoom uas ua tiav cov nyhuv ziab sai sai mus thiab tawm lub nruas nyob rau hauv qhov kev txiav txim ntawm huab cua kub, thiab cov ntaub ntawv ntub dej uas tsis tau mus txog qhov ziab tsis tuaj yeem mus sai sai vim nws qhov hnyav, thiab cov khoom tau qhuav tag rau hauv cov duab plaub. daim hlau, yog li ua tiav lub hom phiaj ziab.

Qhov zoo

1. Peb lub tog raj kheej qauv ntawm lub nruas ziab kom qhov chaw sib cuag ntawm cov khoom ntub thiab cov cua kub, uas txo lub sij hawm ziab los ntawm 48-80% piv nrog cov tshuaj ib txwm siv, thiab cov dej noo evaporation tuaj yeem ncav cuag 120-180 kg. / m3, thiab cov roj noj yog txo los ntawm 48-80%.Kev siv yog 6-8 kg / ton.

2. Kev ziab ntawm cov khoom siv tsis yog tsuas yog ua los ntawm cov cua kub ntws, tab sis kuj ua los ntawm cov hluav taws xob infrared ntawm cov hlau rhuab hauv, uas txhim kho qhov kev siv cua sov ntawm tag nrho lub tshuab ziab khaub ncaws.

3. Tag nrho qhov loj ntawm lub tshuab ziab khaub ncaws yog txo los ntawm ntau tshaj 30% piv rau ib lub tog raj kheej tshuab ziab khaub ncaws, yog li txo cov cua sov sab nraud.

4. Lub thermal efficiency ntawm tus kheej-insulating tshuab ziab khaub ncaws yog siab li 80% (piv rau 35% nkaus xwb rau lub tshuab ziab khaub ncaws), thiab thermal efficiency yog 45% siab dua.

5. Vim lub compact installation, pem teb qhov chaw yog txo los ntawm 50% thiab tus nqi infrastructure yog txo los ntawm 60%

6. Qhov kub ntawm cov khoom tiav tom qab ziab yog li 60-70 degrees, yog li ntawd nws tsis xav tau lub tshuab txias ntxiv kom txias.

7. Qhov kub ntawm cov pa tawm yog tsawg, thiab lub neej ntawm lub hnab lim plua plav yog txuas ntxiv 2 zaug.

8. Qhov xav tau kawg cov av noo tuaj yeem hloov kho tau yooj yim raws li cov neeg siv khoom xav tau.

Khoom parameters

| Qauv | Sab nraud lub tog raj kheej dia.(м) | Sab nraud lub tog raj kheej ntev (м) | Rotating ceev (r/min) | Ntim (m³) | Qhuav muaj peev xwm (t / h) | Lub zog (kw) |

| TIAB SA 1520 | 1.5 | 2 | 3-10 | 3.5 | 3-5 | 4 |

| TIAB SA 1530 | 1.5 | 3 | 3-10 | 5.3 | 5-8 | 5.5 |

| TIAB SA 1840 | 1.8 | 4 | 3-10 | 10.2 | 10-15 | 7.5 |

| TIAB SA 1850 | 1.8 | 5 | 3-10 | 12.7 ib | 15-20 | 5.5 * 2 |

| TIAB SA 2245 | 2.2 | 4.5 | 3-10 | 17 | 20-25 | 7.5 * 2 |

| TIAB SA 2658 | 2.6 | 5.8 | 3-10 | 31 | 25-35 | 5.5 * 4 |

| TIAB SA 3070 | 3 | 7 | 3-10 | 49 | 50-60 | 7.5 * 4 |

Nco tseg:

1. Cov kev ntsuas no yog xam raws li qhov pib ntawm cov xuab zeb noo noo: 10-15%, thiab cov av noo tom qab ziab yog tsawg dua 1%..

2. Qhov kub ntawm qhov nkag ntawm lub tshuab ziab khaub ncaws yog 650-750 degrees.

3. Qhov ntev thiab txoj kab uas hla ntawm lub tshuab ziab khaub ncaws tuaj yeem hloov tau raws li cov neeg siv khoom xav tau.

Cyclone

Nws txuas nrog lub qhov hluav taws xob cua ntawm lub tshuab ziab khaub ncaws kawg los ntawm lub raj xa dej, thiab tseem yog thawj cov khoom siv tshem tawm plua plav rau cov roj kub kub hauv lub tshuab ziab khaub ncaws.Muaj ntau hom qauv xws li ib qho cua daj cua dub thiab ob pawg cua daj cua dub tuaj yeem xaiv.

Impulse plua plav collector

Nws yog lwm cov khoom siv tshem tawm plua plav hauv cov kab ziab khaub ncaws.Nws sab hauv ntau pawg lim hnab qauv thiab cov qauv siv dav hlau mem tes tuaj yeem lim thiab khaws cov plua plav hauv cov plua plav-dawb, kom cov plua plav cov ntsiab lus ntawm cov pa tawm tsawg dua 50mg / m³, kom ntseeg tau tias nws ua tau raws li kev tiv thaiv ib puag ncig.Raws li kev xav tau, peb muaj ntau tus qauv xws li DMC32, DMC64, DMC112 rau xaiv.

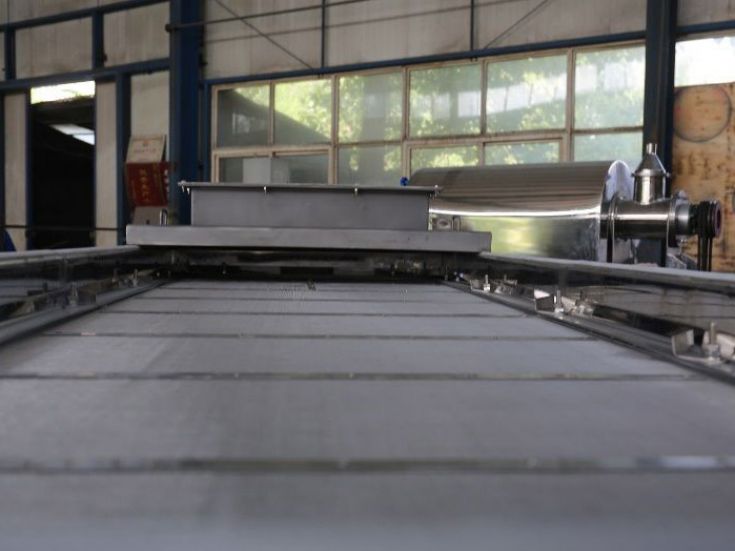

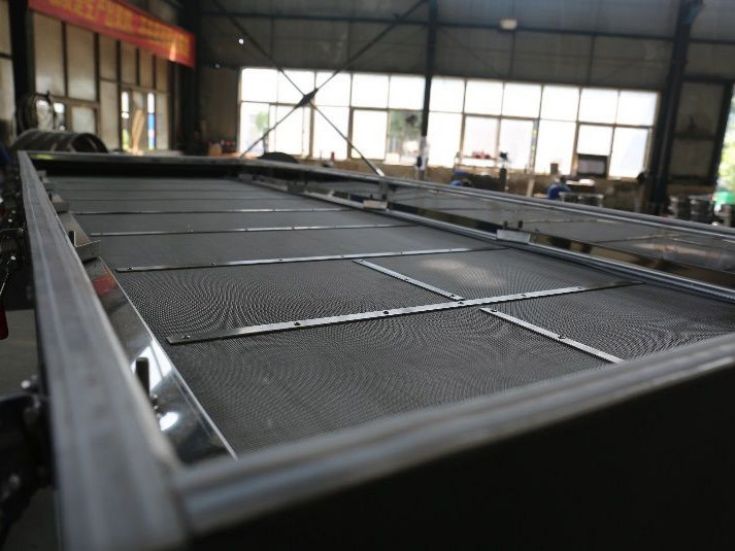

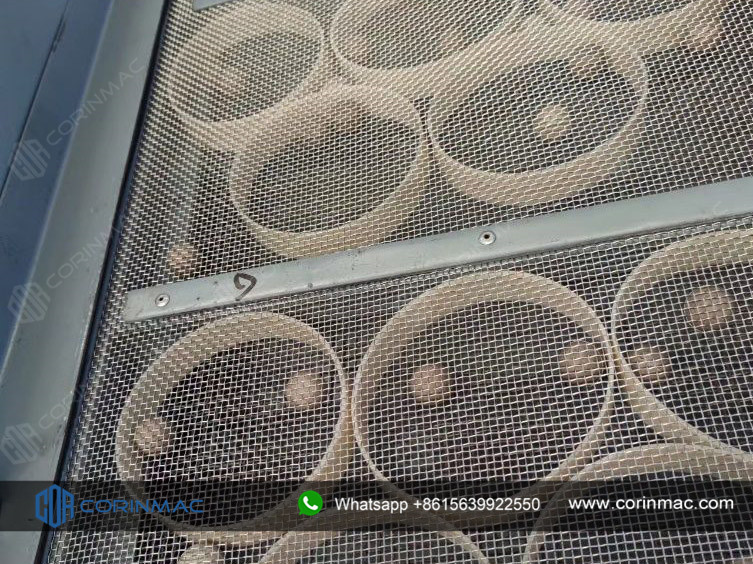

Vibrating npo

Tom qab ziab, cov xuab zeb tiav lawm (dej cov ntsiab lus feem ntau qis dua 0.5%) nkag mus rau hauv lub vibrating npo, uas tuaj yeem ua sieved rau hauv qhov sib txawv me me thiab tso tawm los ntawm cov chaw nres nkoj raws li qhov xav tau.Feem ntau, qhov loj ntawm qhov screen mesh yog 0.63mm, 1.2mm thiab 2.0mm, qhov tshwj xeeb mesh loj yog xaiv thiab txiav txim siab raws li qhov xav tau tiag tiag.

Txhua lub npov steel ncej, tshwj xeeb npo qhov cuab yeej cuab tam, yooj yim los hloov lub vijtsam.

Muaj cov khoom siv roj hmab elastic, uas tuaj yeem tshem tawm qhov thaiv qhov screen

Ntau qhov kev txhawb nqa ribs, ntau zog thiab txhim khu kev qha

Electronic tswj qhov system

Tag nrho cov kab ntau lawm yog tswj nyob rau hauv ib qho kev sib koom ua ke, nrog rau kev pom kev ua haujlwm, los ntawm kev hloov pauv zaus los kho qhov ceev ntawm cov khoom noj thiab ziab ziab rotates, ntse tswj lub burner, thiab paub txog kev tswj kub thiab lwm yam haujlwm.

Sand drying production plant technical parameter

| Cov npe khoom siv | Peev xwm (Humidity yog xam raws li 5-8%) | |||||

| 3-5 TSI | 8-10 TSI | 10-15 TSI | 20-25 TSI | 25-30 TSI | 40-50 TSI | |

| Wet sand hopper | 5T | 5T | 5T | 10 T | 10 T | 10 T |

| Belt feeder | PWG 500 | PWG 500 | PWG 500 | Ф500 | Ф500 | Ф500 |

| Siv conveyor | wb 500x6 | wb 500x8 | wb 500x8 | 500x10 | 500x10 | 500x15 |

| Peb lub tog raj kheej teb tshuab ziab khaub ncaws | TIAB SA 6205 | TIAB SA 6210 | TIAB SA 6215 | TIAB SA 6220 | TIAB SA 6230 | TIAB SA 6250 |

| Hlawv chamber | Txhawb nqa (nrog rau refractory cib) | |||||

| Burner (Npaj / Diesel) Thermal zog | RS/RL 44 T.C 450-600 kWm | RS/RL 130 T.C 1000-1500 kWm | RS/RL 190 T.C 1500-2400 kWm | RS/RL 250 T.C 2500-2800 kWm | RS/RL 310 T.C 2800-3500 kWm | RS/RL 510 T.C 4500-5500 kWm |

| Khoom siv conveyor | wb 500x6 | wb 500x6 | wb 500x6 | wb 500x8 | 500x10 | 500x10 |

| Vibrating screen (Xaiv lub vijtsam raws li qhov loj me ntawm cov khoom tiav) | TZS 1025 | TZD 1230 | TZD 1230 | TIAB SA 1540 | DZS 1230 (2 台) | DZS1530 (2sets) |

| Siv conveyor | wb 500x6 | wb 500x6 | wb 500x6 | wb 500x6 | wb 500x6 | wb 500x6 |

| Cyclone | Φ500 hli | Φ1200 hli | Φ1200 hli | Φ1200 | Φ1400 Nws | Φ1400 Nws |

| Draft fan | Y5-47-5C (5.5kw) | Y5-47-5C (7.5kw) | Y5-48-5C (11kw) | Y5-48-5C (11kw) | Y5-48-6.3C 22 kwb | Y5-48-6.3C 22 kwb |

| Pulse plua plav collector |

|

|

|

|

| |

Installation thiab commissioning

CORINMAC muab kev pabcuam rau ntawm qhov chaw thiab commissioning.Peb tuaj yeem xa cov kws tshaj lij engineers rau koj qhov chaw raws li koj qhov yuav tsum tau ua thiab cob qhia cov neeg ua haujlwm hauv tsev los ua haujlwm cov khoom siv.Peb kuj tuaj yeem muab cov kev pab cuam qhia kev teeb tsa video.

Kev kos duab

Peb cov khoom

Cov khoom pom zoo

Peb lub tog raj kheej teb tshuab ziab khaub ncaws nrog kub kub eff...

Nta:

1. Tag nrho qhov loj ntawm lub tshuab ziab khaub ncaws yog txo los ntawm ntau tshaj 30% piv rau tib lub tog raj kheej rotary tshuab ziab khaub ncaws, yog li txo cov cua sov sab nraud.

2. Lub thermal efficiency ntawm tus kheej-insulating tshuab ziab khaub ncaws yog siab li 80% (piv rau 35% nkaus xwb rau lub tshuab ziab khaub ncaws), thiab thermal efficiency yog 45% siab dua.

3. Vim lub compact installation, pem teb qhov chaw yog txo los ntawm 50%, thiab tus nqi infrastructure yog txo los ntawm 60%.

4. Qhov kub ntawm cov khoom tiav tom qab ziab yog li 60-70 degrees, yog li ntawd nws tsis xav tau lub tshuab txias ntxiv kom txias.

Rotary tshuab ziab khaub ncaws nrog tsawg zog noj thiab hi ...

Nta thiab qhov zoo:

1. Raws li cov ntaub ntawv sib txawv kom qhuav, qhov tsim nyog tig lub tog raj kheej tuaj yeem xaiv tau.

2. Kev ua haujlwm du thiab txhim khu kev qha.

3. Cov khoom siv hluav taws xob sib txawv muaj xws li: roj av, diesel, thee, biomass hais, thiab lwm yam.

4. ntse tswj qhov kub thiab txias.